Easy-to-assemble

components

Lignotrend makes timber construction simple, precise and cost-effective

The configurable, load-bearing LIGNO® components for ceiling and roof are precisely prefabricated in the Lignotrend factory in the context of a digital process chain. Due to the installation-ready and therefore very assembly-friendly preparation/pre-assembly, the construction time on site is shortened and the construction costs are also reduced. LIGNO® standard walls as well as the acoustic panels for cladding are also characterized by particularly high precision. They can easily be further processed in carpenter's workshops or on the construction site and installed with a precise fit.

The basis of high precision

Dimensionally stable cross-laminated timber

When components are dimensionally stable, movements in the building structure and thus deformations and leaks are effectively excluded. This is why Lignotrend's web and box elements are also made of timber layers arranged crosswise to form rigid, precise cross-laminated timber, which is the best prerequisite for precisely fitting components.

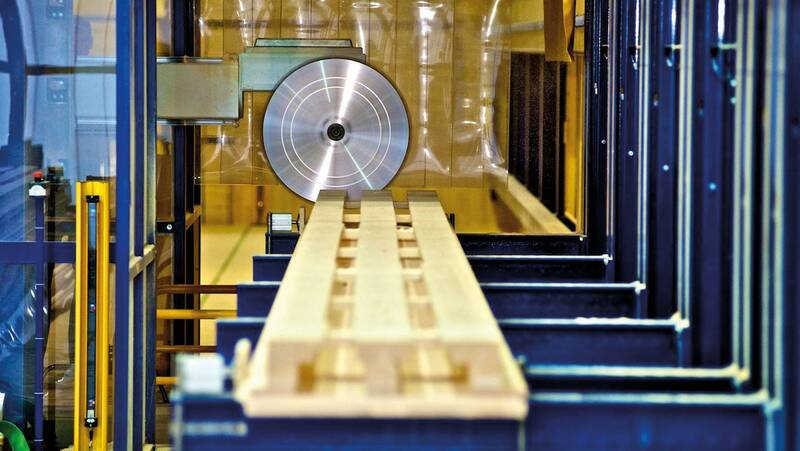

Ready to install thanks to precise cutting to size

CNC joinery

To ensure that everything fits perfectly during assembly on the building site, all cutting work for the cross-laminated timber ceiling and roof elements from Lignotrend is carried out in the factory on highly precise CNC joinery machines. This includes straight, angled or round cuts, jaggings and the integration of joists or the preparation of exits for the building services. The components can thus be installed immediately on the building site.

Fast building sites with timber construction

Pre-assembly saves time

Ceiling and roof components The pre-assembly of several element strips in the factory to form large panels is common here. The dimensions are based on the technical possibilities of prefabrication as well as on limitations in transport and assembly. The maximum size of a large panel is 2.50 x 18 metres.

Wall components The standard floor-to-ceiling cross-laminated timber modules with a width of 625 mm, on the other hand, are usually joined together to make complete wall components in timber construction. They are provided with all openings and details, sometimes up to the complete wall, supplemented by insulation, façade and windows. On request, Lignotrend can also supply the house construction kit pre-assembled ex works – a welcome option for timber construction companies in times of good capacity utilisation.

Quickly assembled = quickly rainproof

Secure against moisture

Due to the fast assembly time on the building site that results from the high degree of prefabrication, the construction progress is significantly less influenced by the weather. If, when using roof elements, the lower seal acting as an "emergency roof" is applied immediately after installing the first load-bearing elements, the roof is immediately rainproof.

New LIGNO® element generation: Even more resistant to moisture

Further optimised

With regard to its deformation tendency, cross-laminated timber is per se a building material that exhibits good resistance to the moisture changes that can occur in construction. Lignotrend has further improved the elements of the latest LIGNO® Rippe-x and LIGNO® Block-x component generation in terms of moisture resistance in order to further minimise torsion and the risk of optical impairments in case of moisture changes: The joint pattern of the acoustic slat profiles is thus also undisturbed at the joint.

High installation speed

With pre-assembled large elements, the installation of 1,500 square metres per day is also conceivable. Roof shear panels, e.g. in hall construction, are simply placed on the girders.

Load-bearing components: Interior finishing already included

The finished soffit of the elements eliminates the need for time-consuming and labour-intensive interior finishing work – e.g. for the ceiling cladding. Finishing work on the ceiling and the necessary scaffolding are eliminated – and the building is finished faster.

Fast interior finishing in a lightweight large format

Rapid progress can be made in the interior finishing with Lignotrend acoustic elements.